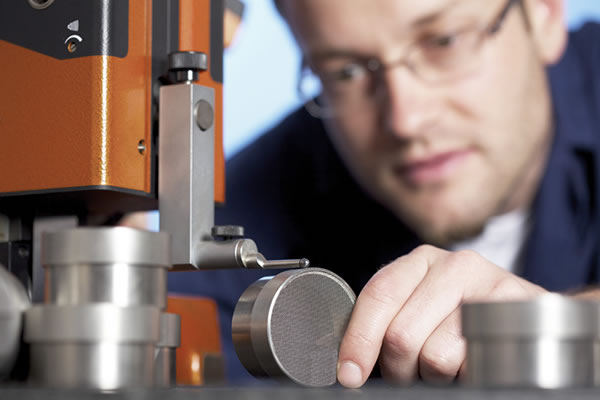

The devices of ElementCheck are masters of versatility. Whether in the jewelry studio or at the factory floor: They are applied where fast, accurate, safe and reliable elemental analyses of metallic materials are required.

Does the supply of metallic materials meet the quality requirements? Is the supply in line with the purchase order? With ElementCheck there is clarity and certainty starting from receipt of goods.

How good are the raw materials to be used in production? Do they meet the requirements? Thanks to ElementCheck the quality of the material - and therefore the final product – agrees well with the specifications.

What's still available in the warehouse in terms of steel, non-ferrous and light metal alloys? ElementCheck enables for reliable and rapid classification of the available raw material. Make more out of your hidden treasure!

Are the machines in your production perfectly adjusted to the materials to be processed? ElementCheck can assume the process control, even fully automatically.

What is the purity of precious metals? Whether the raw material, the finished jewelry or the noble clock: With ElementCheck an accurate, non-destructive analysis without waste of materials, damage, or application of chemicals is possible.

Is a product or a commodity truly lead-free? For a very long time, lead was an important processing additive in the industry - and a large polluter. ElementCheck quickly indicates whether and how much of the toxic heavy metals are present. This helps in the implementation of the EU directive on the use of environmentally hazardous substances (RoHS).